General Info and Tips

This section provides some basic information on using DoD as a source of non-dilutive capital.

- Do they have money?

- Do they have authority to spend money / issue contracts?

- What are their pain points and do they speak for the users?

- What’s stopping them from resolving these pain points today?

- Who else is offering something that appears similar to my product/service?

- Who is currently providing something similar today?

- Who are other potential new suppliers?

- Who loses if DOD buys my product/service?

- Military Departments: Departments of the: Army, Navy, and Air Force

- Not to be confused with Military Services, which also includes the Marine Corps (which falls within the Department of the Navy) and Space Force (which falls within the Department of the Air Force)

- Generally responsible for organizing, training, and equipping military forces

- OSD: Office of the Secretary of Defense; generally responsible for policy across the entire Defense Department

- Defense Agencies: technically under OSD, but with special missions that cut across all Military Services; e.g., Defense Logistics Agency (dla.mil) which has overall responsibility for managing the end-to-end global defense supply chain, from raw materials to user disposition of products once no longer needed

- CCMDs: unified combatant commands; 11 joint military commands, focused on a specific geographic region (e.g., European Command or EUCOM) or functional area (e.g., Special Operations Command or SOCOM)

- Generally, CCMDs rely on one of the military services to procure technology that they need; they also leverage OSD programs to explore new technologies

- SOCOM is the primary exception to this, as they have their own budget and “acquisition authority” (which means they have authority to issue their own contracts)

- For new technologies, CCMDs can be useful as an advocate with an important mission and access to senior officials

- However, because they generally don’t have funding or the ability to issue contracts, the CCMD is not typically a direct customer

- Generally, CCMDs rely on one of the military services to procure technology that they need; they also leverage OSD programs to explore new technologies

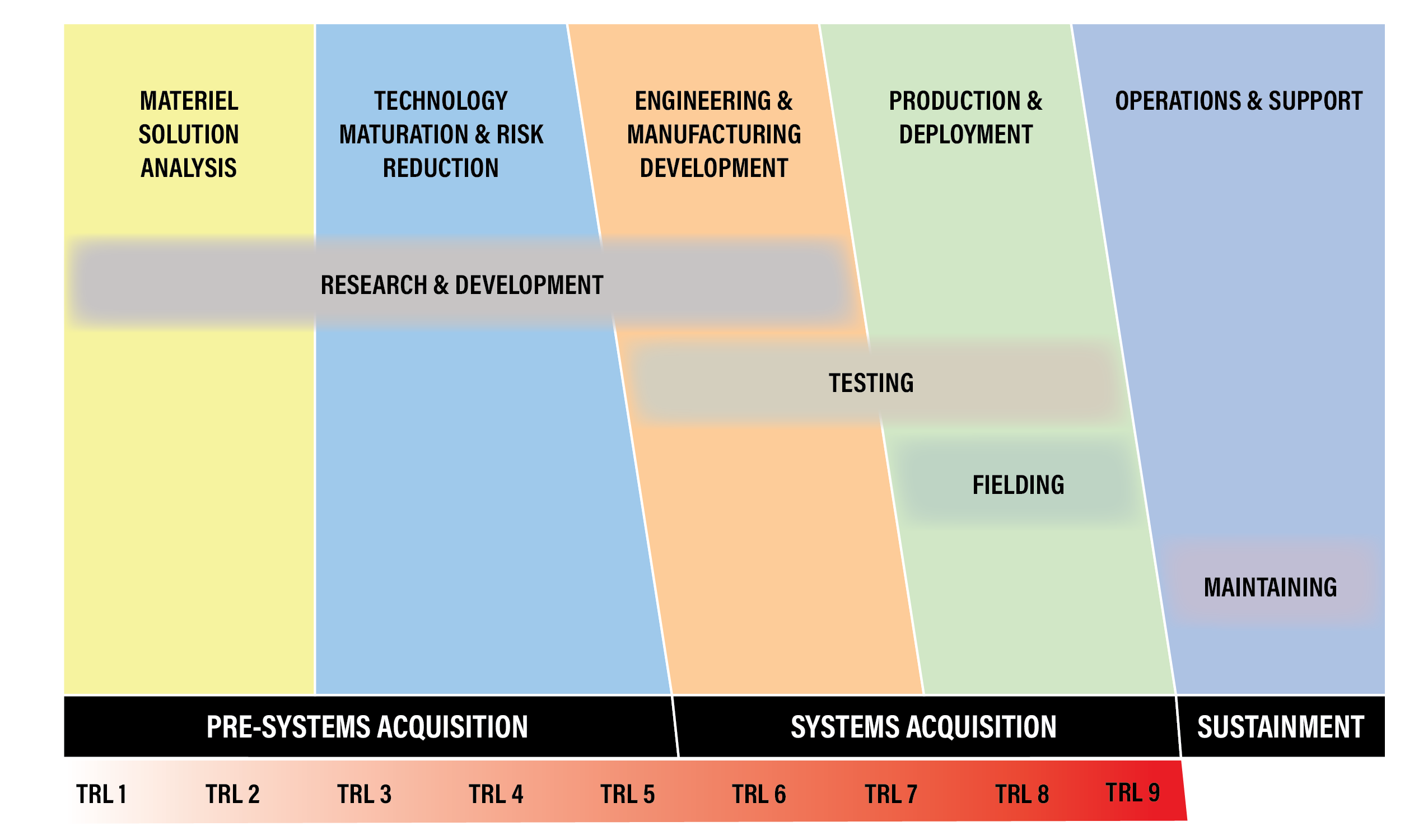

- R&D: research and development, which includes everything from new scientific discoveries through engineering and manufacturing development (i.e., preparing new technologies for mass production)

-

- S&T: science and technology; generally, led by Defense Department Labs (more details under a separate section focused on “Labs”)

- Engineering & manufacturing development: generally, led by various engineering centers and program/project management offices (PMOs) (more details under separate sections on “engineering centers” and “PEOs/PMOs”)

- Testing: includes both developmental testing and operational testing and evaluation

- Note: while historically, end users had minimal involvement in earlier technology development stages, more recently end user engagement has been required earlier in the technology development process, even during the S&T phase conducted by the labs

- Fielding: moving technologies from development into operational use

- Maintaining: maintaining technologies in use; this also includes upgrades to “fielded” technologies

- The main thing to keep in mind about upgrading technologies currently in use is that this is not an area readily available to new companies or new technologies

- Defense prime contractors (or “Primes”; i.e., the companies to whom a major contract is awarded) typically have system upgrades incorporated into the scope of their contract

- This means that companies offering new tech for an existing “fielded system” must go through the Prime to have their technology incorporated (see separate section on “Defense Primes”

-

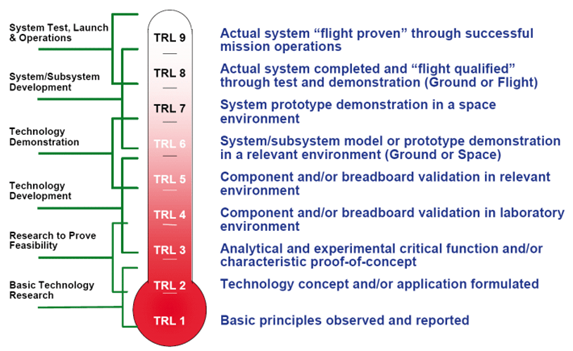

- TRLs provide a standard measure of the maturity of technology

-

- While some DoD offices may conduct a formal TRL assessment to officially determine the TRL of a technology of interest, TRLs are typically informally established by the organization developing the technology and used to help determine whether a technology is at the appropriate maturity level to be of interest to a particular DoD office

-

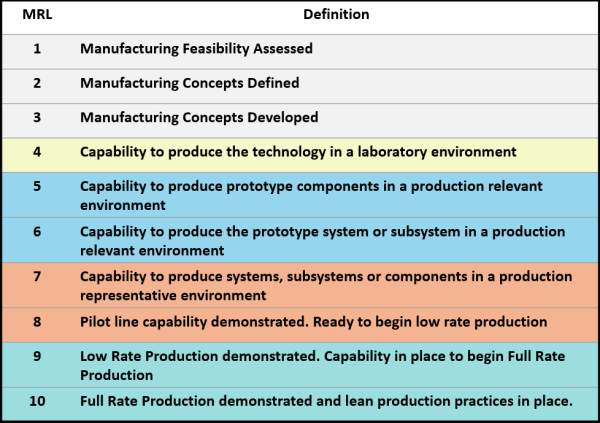

- MRLs were designed to provide a maturity model based on well developed criteria and are patterned after TRLs (method of estimating technology maturity of Critical Technology Elements) that will in identifying the maturity of their manufacturing efforts on a program or a technology